Consistent Accurate Grading

Transparent, merit-based trading card grading with consistent standards, fast turnaround times, and clear communication, so you can submit with confidence.

Consistent Grading

Full Transparency

Unbiased Pricing

Changing The Game

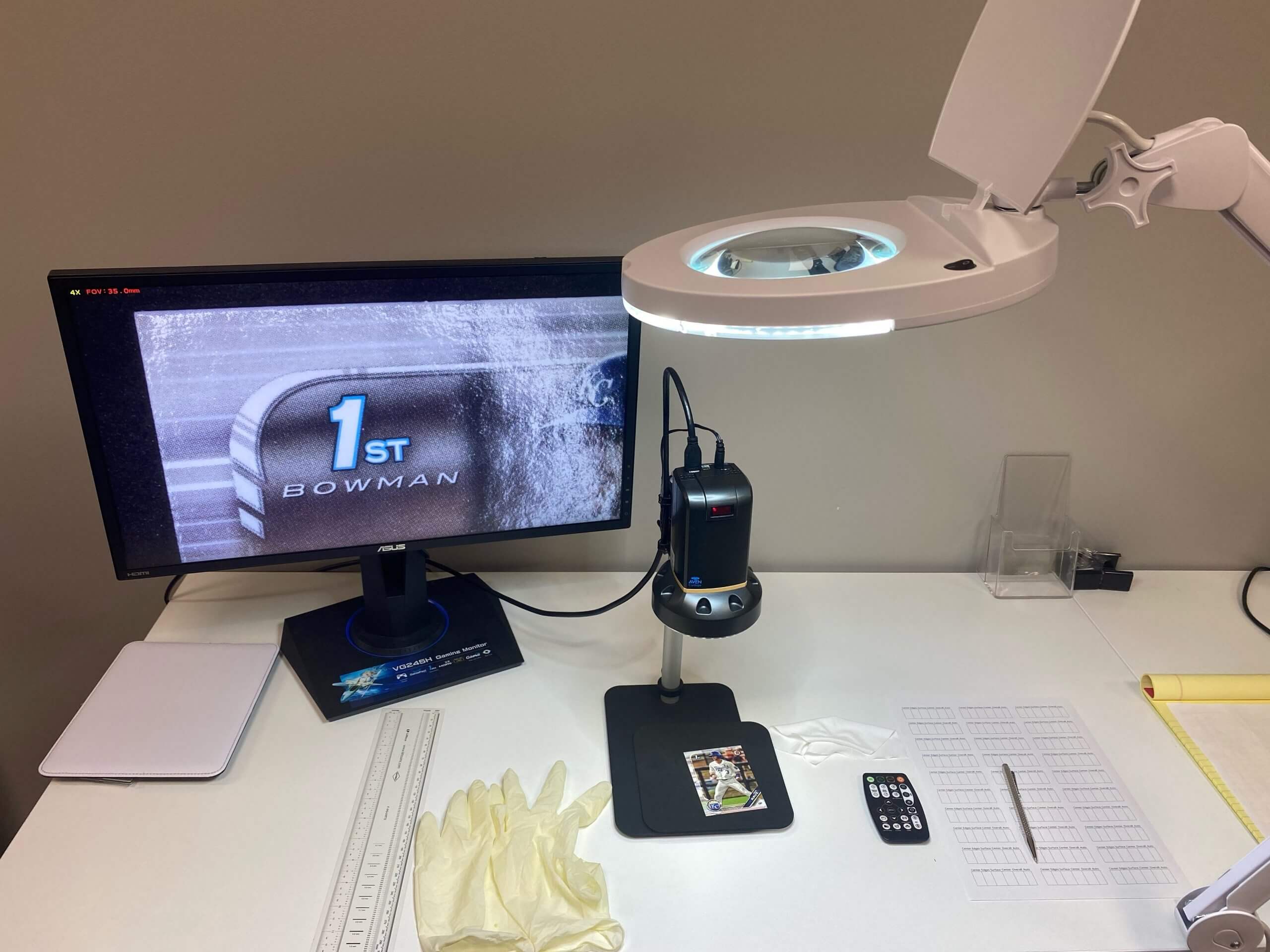

Our graders use professional microscopes with adjustable magnification and multiple light settings, allowing them to examine every card under the ideal conditions. Combined with overhead magnifying lamps and specialized lighting tools, each card is reviewed carefully from every angle.

We follow a clearly published grading scale with full transparency. Every grade and sub-grade is determined by defined criteria—no guesswork, no hidden standards.

Our slabs feature a classic, sharp design with no gimmicks—letting the card speak for itself. Every card passes through strict quality control to prevent mislabeling, spelling errors, or grading inconsistencies.

We deliver consistent turnaround times, meeting or exceeding the service level you choose. Cards are graded solely on their merit—no population control, no bias, no shortcuts.

From the moment your cards arrive to the day they’re safely shipped back, you’ll receive clear communication and reliable customer support every step of the way.

Full Transparency, See How FCG Grading Works

Why Grade with

Forensic Card Grading

Operating under a clearly defined set of rules for subgrades, utilizing intense lighting and high magnification in the review process, we have created an environment where all cards can be evaluated accurately and consistently. Whether you’re grading with FCG or buying an FCG slab in the market, you can trust that the grades on the label are a true representation of the card you’re receiving.

Objective Grading

Full Transparency

Fast Turnaround

Clear Communication

Clean, Classic Slabs

Consistent Results

One Service Level “fast”

10 Days Or Less

$15 Per Card

Money Back Guarantee

If customers cards do not ship within 10 business days from the time they are received at our office, customer is eligible for the money-back guarantee. Days are counted in business days, with day one being the first full business day after the cards arrive at our office, with the day the cards ship counting as fulfillment of our 10 day guarantee/promise.

Submitting Cards For Grading

Has Never Been Easier

Submitting to FCG is simple. Complete the online form, ship your cards securely, and receive your grades electronically once grading is complete, followed by the safe return of your cards.

Forensic Card Grading

545 S Nolen Dr. Suite 300, Southlake, TX 76092

Submit Online

Pack & Ship

Grading & Updates

Safe Return

Grading Scale Explained

Grading Scale Rules

Final grade cannot be more than 1/2 point higher than the lowest subgrade when the lowest subgrade is represented by either Corners or Centering. Final grade can be 1 full point higher than the lowest subgrade when the lowest subgrade is represented by Surface or Edges. When the lowest subgrade is represented by Surface or Edges the final grade is rounded up 1 full point only when all 3 subgrades are 1 point or higher than the lowest subgrade.

In the case of matching lowest subgrades when either of the matching lowest subgrades are represented by Corners or Centering, the final grade cannot exceed that number regardless of the average. With matching lowest subgrades not represented by Corners or Centering the final grade may be up to 1 point higher than the lowest subgrade provided it averages out without rounding up.

Grading Criteria

We grew tired of the lack of transparency in the card grading industry. A card would come back a 9 that looked better than the 10, or vice versa a card would come back a 10 that didn’t deserve it. There was no rhyme or reason and definitely no consistency. We knew there had to be a better way!

These pictures below are not intended to be pretty. The purpose of these pictures is to set forth a clear and transparent standard of grading so that when you grade with us or buy an FCG slab, you know exactly what you are getting.

Corners

10 corner, at least 3 of the 4 corners are sharp with allowance for very minor rounding on one of the 4 corners.

9.5 corner, tiny bit of rounding. If 1 or 2 of the corners look like this and 2 or 3 of the corners are sharp 10’s, you’re looking at a 9.5 corner subgrade.

9 corner, little bit more rounding, the rounding is a little deeper into the corner. If 3 of the corners are 10’s, and one is a 9, you’re looking 9.5 corner subgrade.

Another 9 corner, sharpness of the corner is gone, rounded corner. If 2 of the corners are like this, regardless of whether the other corners are 10’s or 9.5’s, it’s a 9 corner subgrade.

8.5 corner, 8.5 is really where damage is easily detected by the naked eye. When damage is evident the corner subgrade will be based on the damaged corner regardless of how strong the other corners may be.

Another example of an 8.5 corner, bordering on an 8. Visual damage, the structure of the corner is gone.

Edges

10 edge, majority of the edge is perfectly straight, no fraying, very small allowance for imperfection.

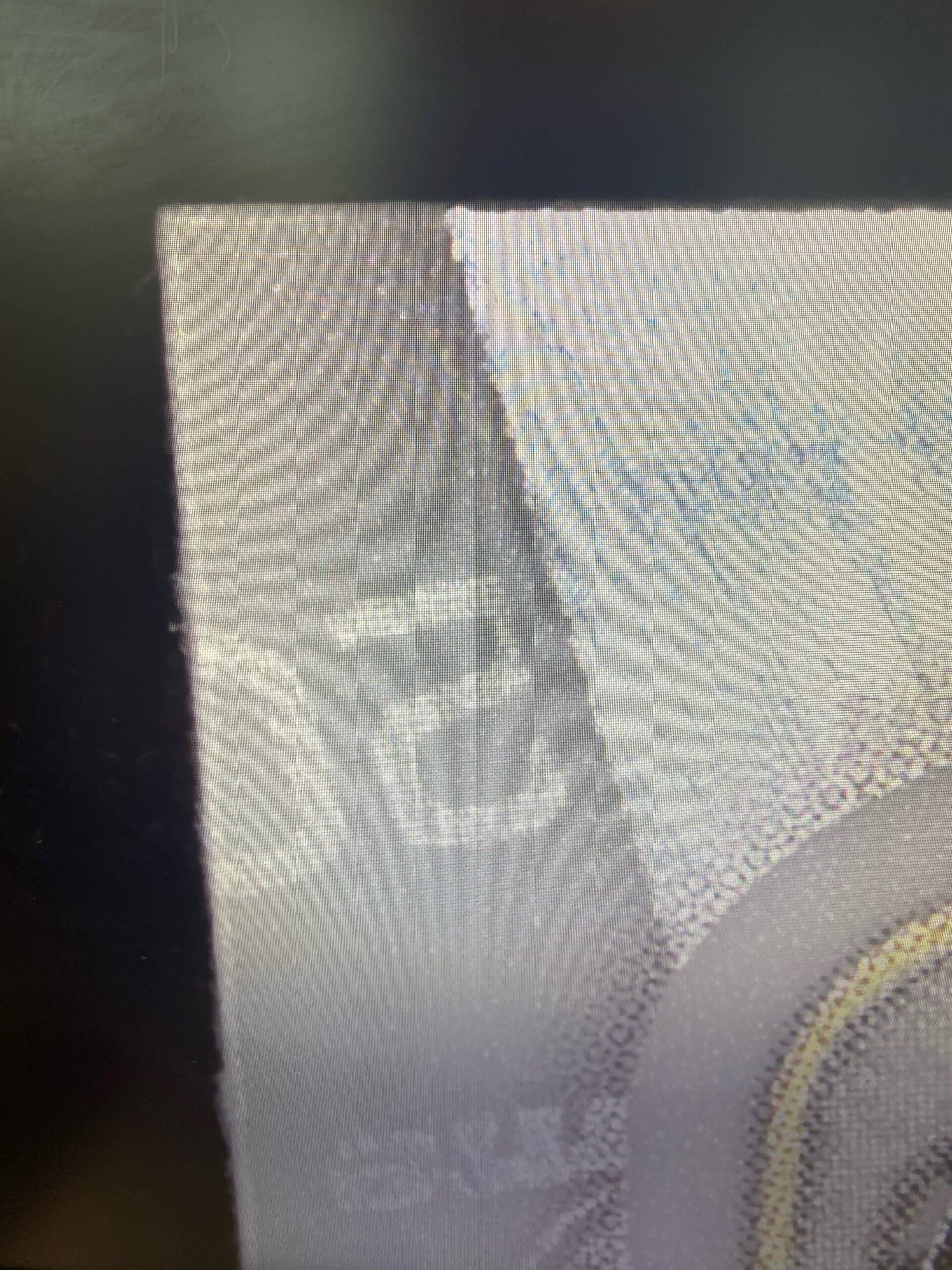

Here you start to see some fraying, some unevenness along the edge as well. If the majority of the edge is in 10 shape and only a small portion of the edge has very minor fraying but the majority is straight, you’re looking at a 9.5 edge subgrade.

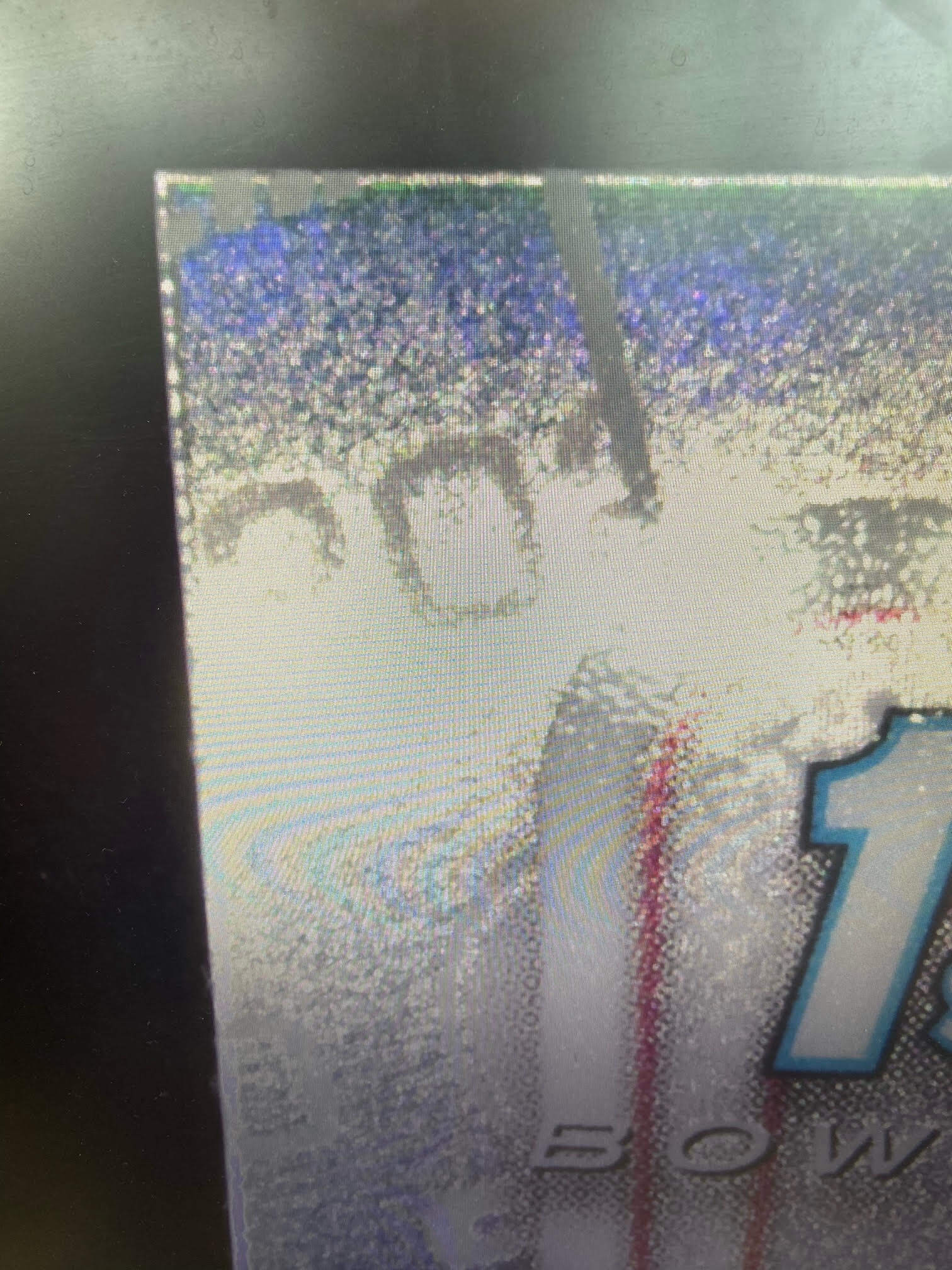

In this pic the fraying is more severe, the edge appears jagged. If large portions of the edge look like this you’re looking at a 9 subgrade, possibly 8.5 depending upon severity.

In this picture you can see unevenness on the cut, fraying, this would result in a 9 or lower edge subgrade.

Surface

A 10 surface grade is for the most part void of any surface flaws, nothing visible to the naked eye, allowance for small imperfections under magnification.

A 9.5 surface grade would indicate that something along the lines of a scratch, dent, print line, or smudge are present.

This is an example of a fingerprint, surface grades will be knocked down if there are smudges and or fingerprints.

Cross lighting allows for surface dents to be picked up on with ease. This indent is barely visible to the naked eye and came from a cracked 9 slab from a competitor

Another example of a surface dent.

Another example of a print line.

Here is a picture of a minor scratch, while it looks major while magnified and under intense light, this scratch is barely visible to the naked eye.

Another example of a surface dent, this one a little bit more major in nature. Were this the only flaw on the surface it would be a 9 subgrade due to the severity of the flaw.

Print line with evidence of smudging next to it as if someone tried to rub the line out and not only didn’t get the line out but left behind finger prints with it.

As a whole when surface imperfections are evident, the severity of the imperfection and whether there are other imperfections will ultimately dictate the surface subgrade

Centering

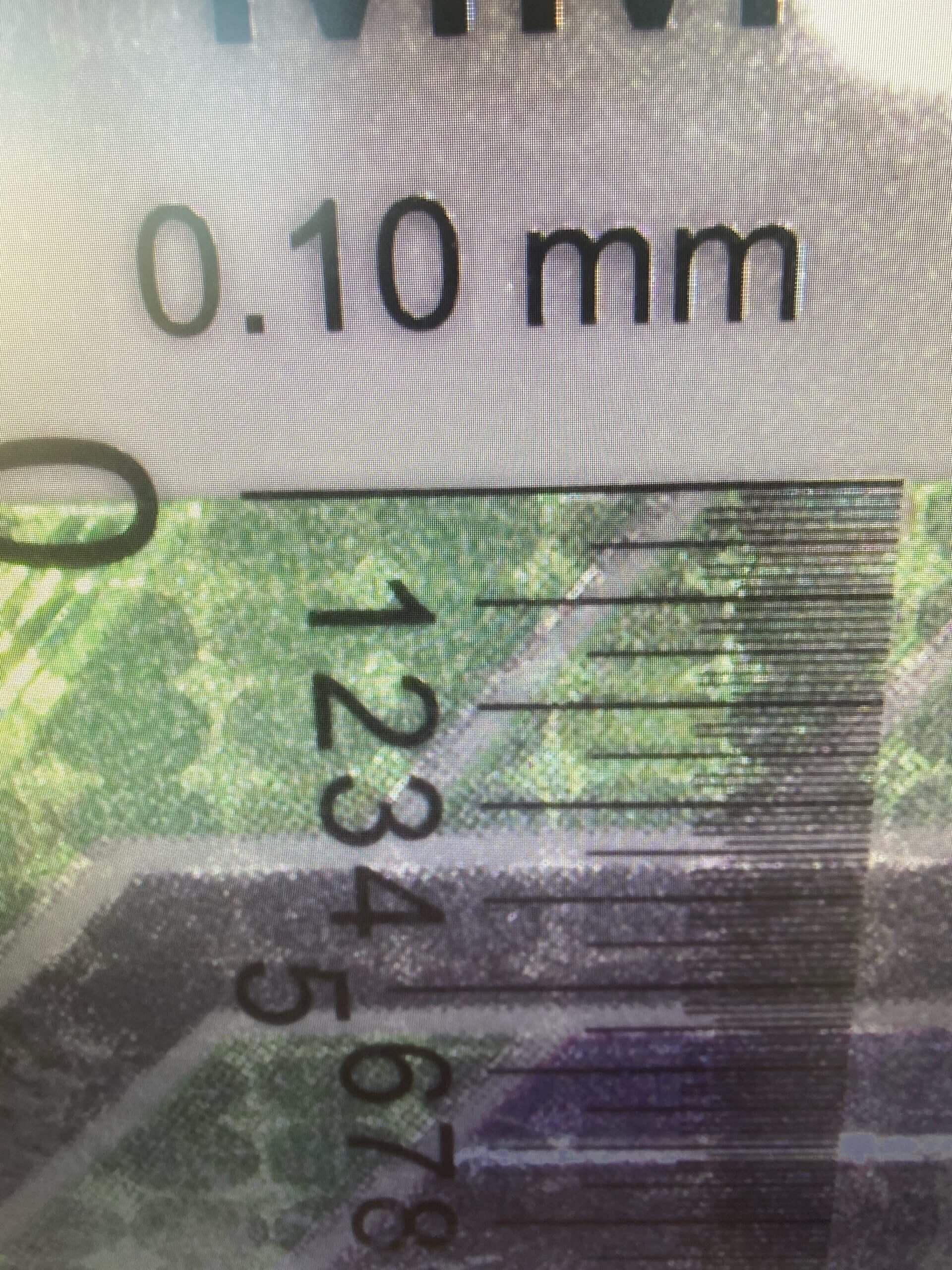

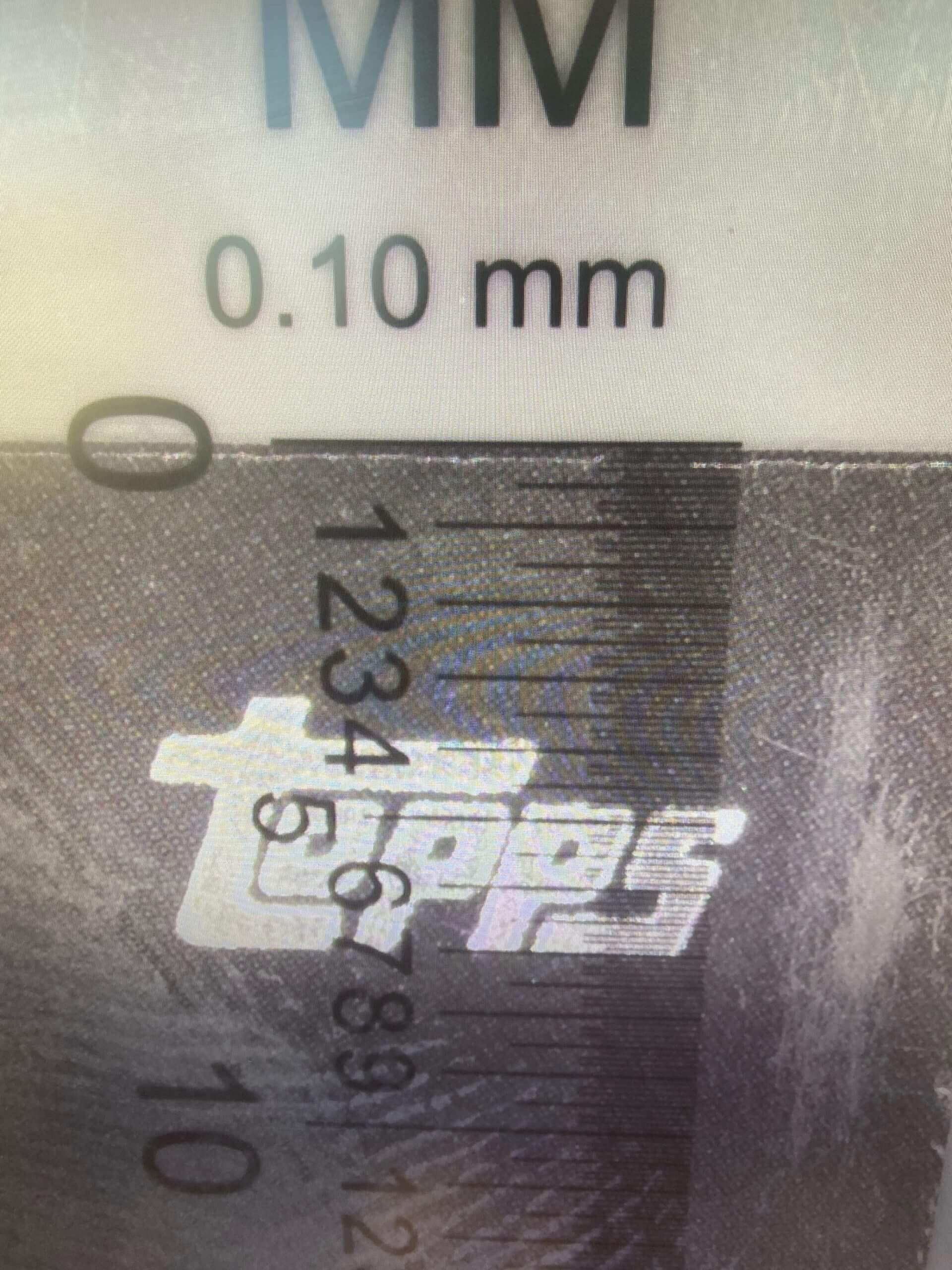

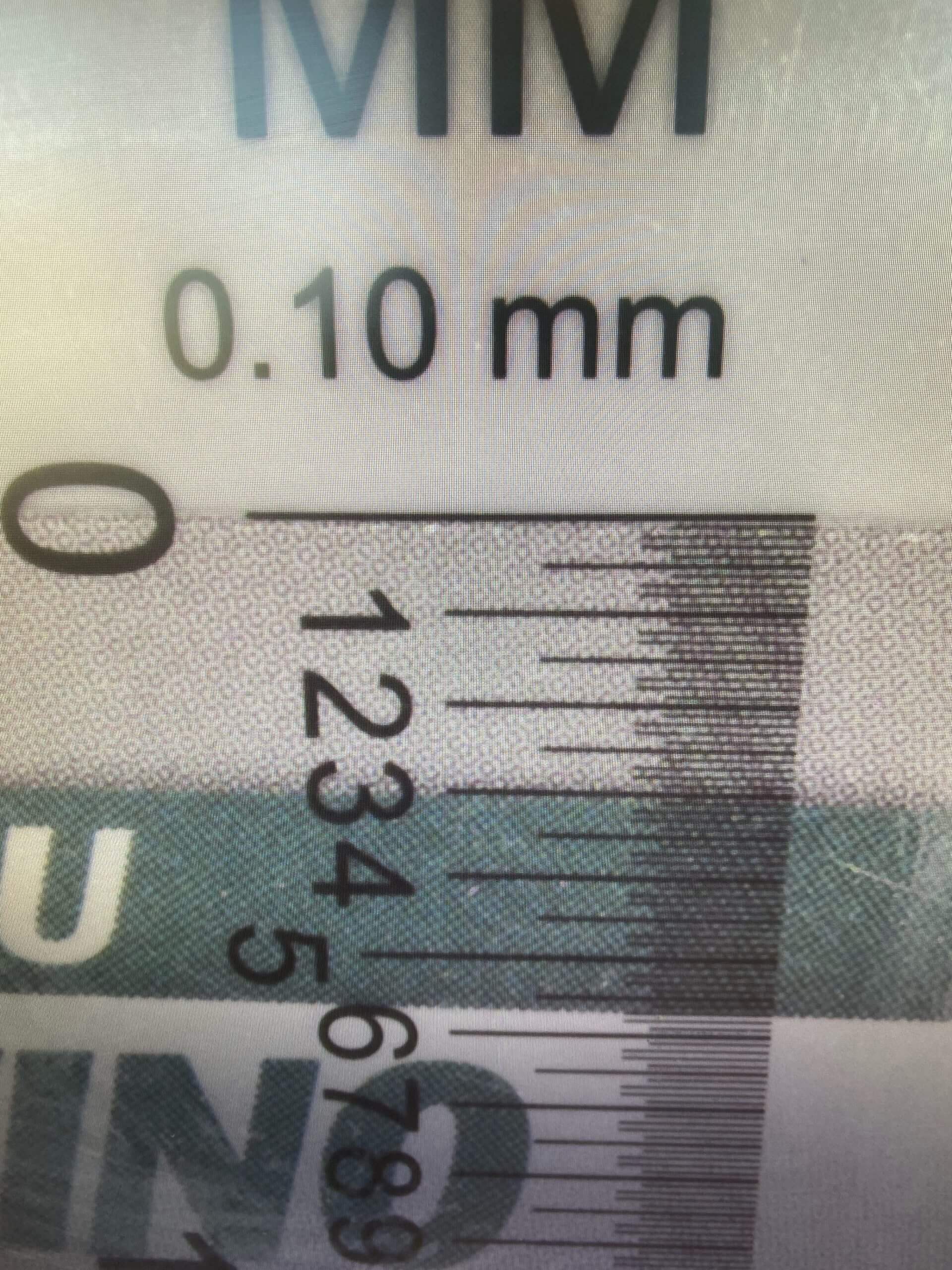

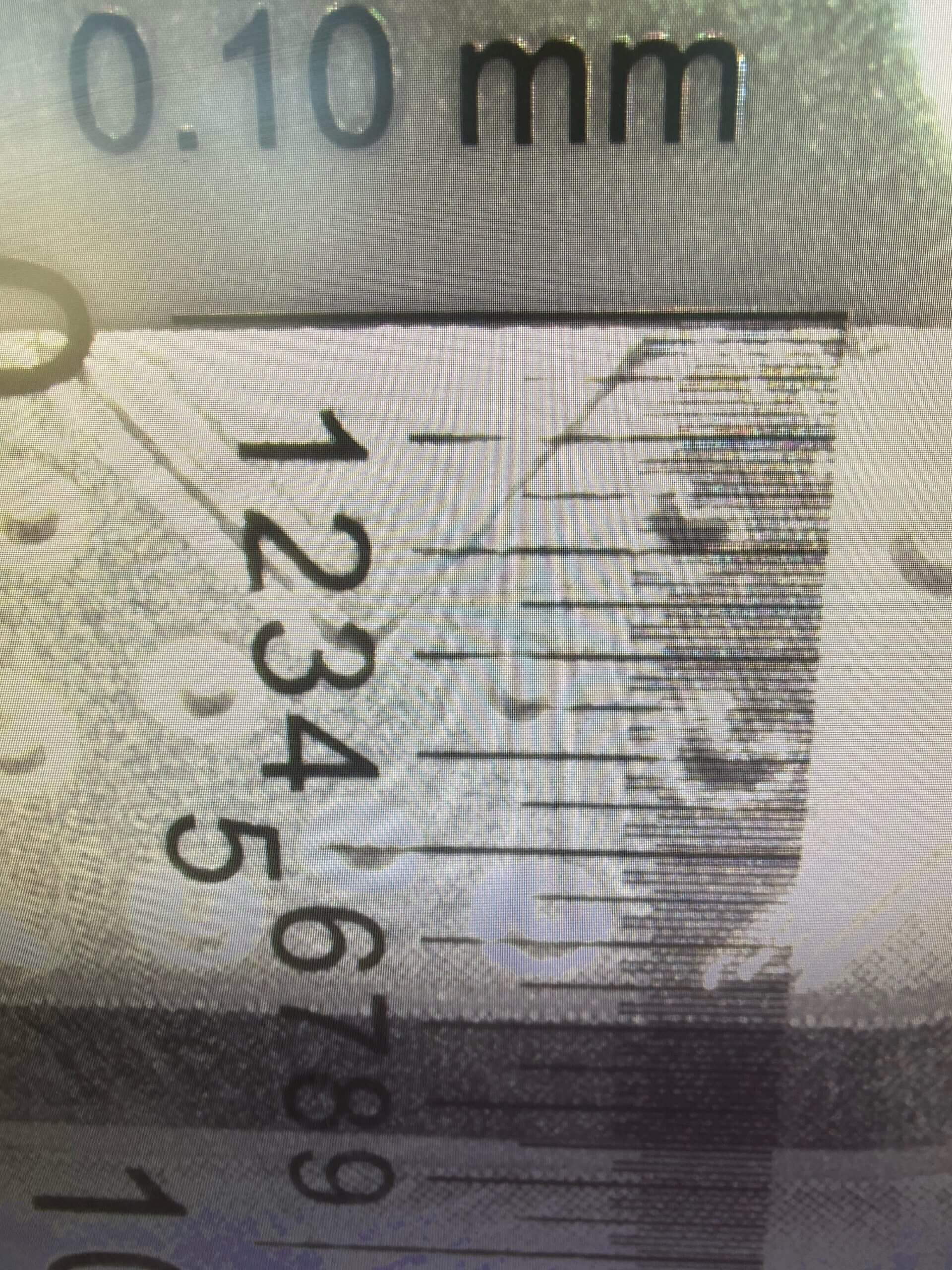

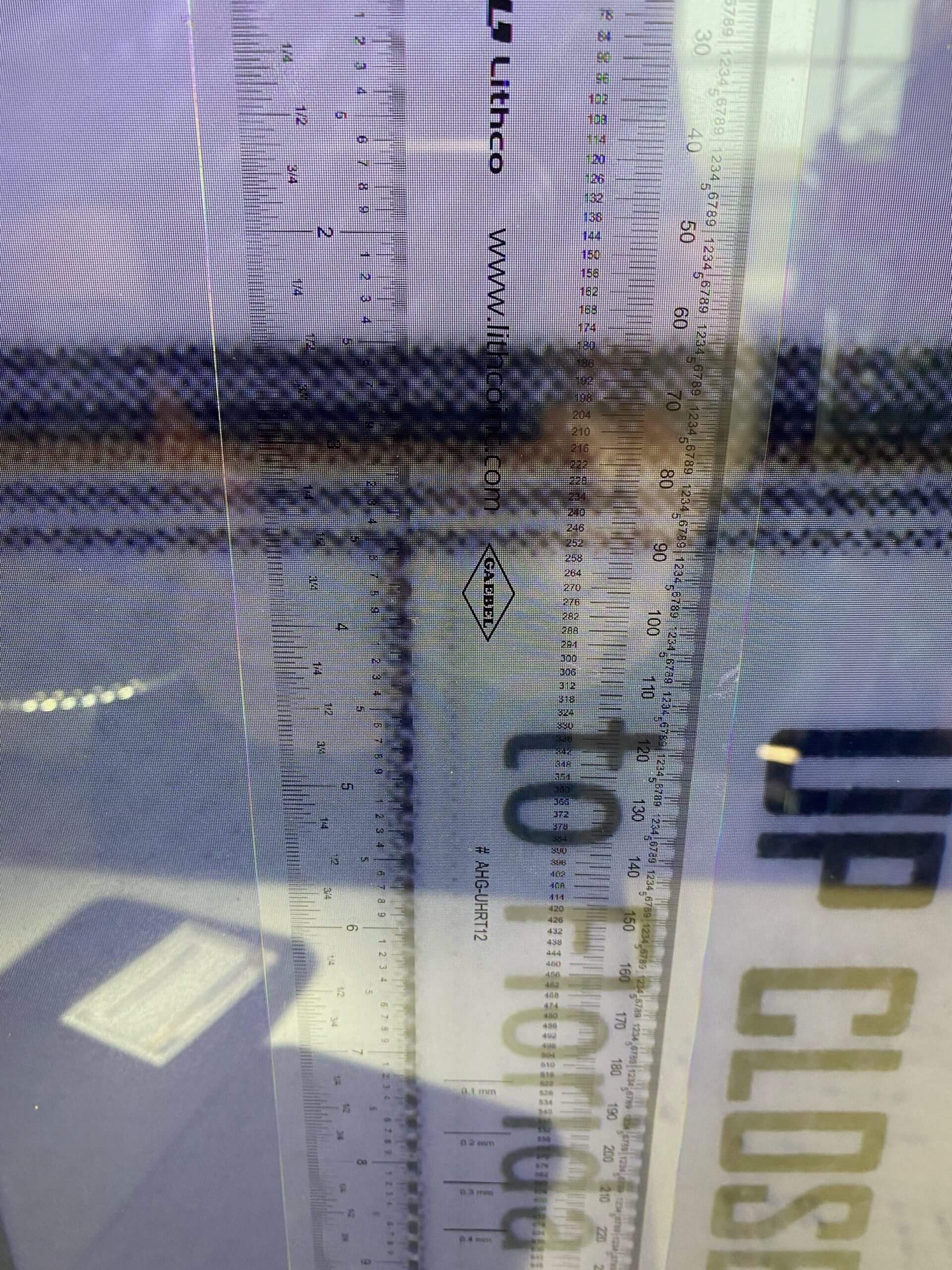

Measuring borders accurately on the card itself can prove to be a challenge. Instead of measuring on the card, we blow up images of the borders.

This allows us to measure using 1/10ths of a millimeter.

We then subtract the difference between the two borders and divide that by the total.

To scale 7% and under results in a 10 center grade.

7-10% 9.5 center grade.

10-13% results in a 9 center grade. Additionally when top to bottom centering is a factor the same process is performed.

Centering of 80/20 or worse on the back of the card will result in a .5 deduction from the overall centering grade.

Questions? Contact FCG

Have questions about submissions, grading, or turnaround times? Our team is here to help and ready to respond.

Questions? Contact FCG

Have questions about submissions, grading, or turnaround times? Our team is here to help and ready to respond.

Questions? Contact FCG

Have questions about submissions, grading, or turnaround times? Our team is here to help and ready to respond.